With the development of science and technology, many new functional materials and products come onto the market. NDC, keeping up with marketing demands, cooperated with medical experts and developed a variety of special equipment for the medical industry. Especially at the critical moment when COVID-19 ravages the world in the past three years, NDC provides strong machines to guarantee for manufacturers who produce protective clothing materials in the medical industry. We also obtained high-rated social recognition and praise from many medical enterprises and the government.

NDC coating technology process can be divided into three ways, we choose the best coating technology according to the product functional requirements and adhesive characteristics.

1.Gravure Anilox Roller Transfer Coating Technology

Gravure Anilox Roller coating is a traditional coating method, just like gravure printing technology. Hot melt adhesive is applied to non-woven fabric through a carved anilox roller with a slot scraper. It is an irreplaceable coating method for patterned coating technology, which can realize the breathable demand.

However, if you want to adjust the adhesive coating amount, you need to replace the coating roller with different depth and shape anilox rollers.

Anilox roller coating method is suitable for a wide range of glues, including PUR adhesive, which is easy to clean. Other hot melt adhesives are easily carbonized by this open heating mode.

2.Spray (non-contact spray adhesive) Coating Technology

Spray coating is a regular coating method. There are two types of spray guns: a small spiral spray gun and a fiber spray gun.

The advantage is that it can be sprayed directly on materials that are not resistant to high-temperature, and the materials have good air permeability, and it’s convenient to adjust the spray weight and width. This is the spray gun’s advantage. The disadvantage is that the nozzle will be inevitably blocked and not easy to clean, and in the production process there will be leakage spray and glue drop phenomena, which will cause defects in the product. Spray coating is not recommended for PUR hot melt adhesive.

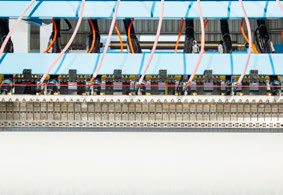

3.Contact Slot Die Breathable Coating Technology

Contact slot die breathable coating is an advanced coating method that can meet low glue coating amount to high coating amounts application. Good coating uniformity, good lamination flatness, easy to adjust glue weight and coating width. It is widely applied in the coating & laminating production lines of isolation clothing materials/self-adhesive medical tape materials, medical dressing paste materials medical plaster materials etc.

NDC has reached the maximum 3600mm machine width for customers. Anilox Roller coating speed 200m/min, non-contact spray coating speed 300m/min and contact breathable coating speed 400m/min.

Technology requires precipitation, experience needs to be accumulated, manufacturing capacity requires investment.

NDC always adheres to its mission of promoting the development of hot melt adhesive spraying and coating technology application. We are dedicated to providing special equipment and technical solutions for hot melt adhesive applications in different industries.

Post time: Apr-06-2023